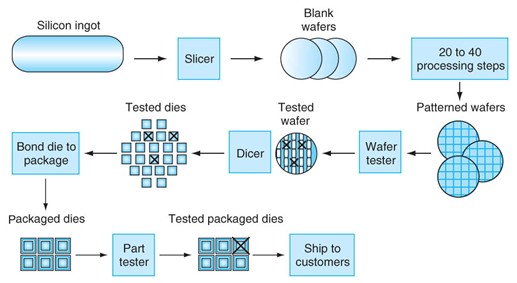

The manufacturing process of integrated circuit takes the following steps:

|

|

|

|

|

- Then, the wafers are diced into dies or chips, each of which is the individual rectangular sections. Dicing enables you to discard only those dies that contain the flaws, rather than the whole wafer.

- The yield is the percentage of good dies from the total number of dies on the wafer. In the previous figure, one wafer produced 20 dies, of which 17 passed testing. (X means the die is bad.) The yield of good dies in this case was 17/20, or 85%.

- These good dies are then bonded into packages and tested one more time before shipping the packaged parts to customers. One bad packaged part was found in this final test.